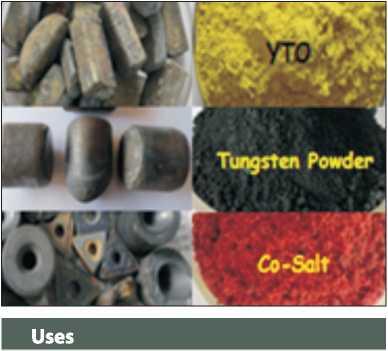

Yellow Tungsten Oxide and Tungsten Metal Powder from Fleavy Alloy Scraps

| 1. | Title of Product/Design/Equipment | Yellow Tungsten Oxide and Tungsten Metal Powder from Fleavy Alloy Scraps |  |

| 2. | IPR Status Patent/Abroad IPR Details | Patent Filed | |

| 3. | Application/Uses | Tungsten recovery from Scrap | |

| 4. | Salient Technical Features including Competing Features | Recovery of high pure products (YTO, W-metal powders & other metal salts/powders) from waste/end-of-life WC-hard metal tool bits/drill bits/inserts etc., and heavy metal alloy scraps/swarf.The salient features of the process are:

| |

| 5. | Level/Scale of Development | Process demonstrated at 1 kg/batch scale | |

| 6. | Environmental Considerations | No solid/liquid effluent generated. ~0.25MT of C02/MT of W-powder. Storage & handling of flammable H2 gas. | |

| 7. | Status of Commercialization | The process has been licensed to M/s Bharat Futuristic Corporation, Bangalore and M/s Minestone Minerals Ltd., Mangalore | |

| 8. | Major Raw Materials to be Utilized | (i) WC scraps, (ii) commercial mineral acids, (iii) EXCEL Grade N2& H2 gasses. | |

| 9. | Major Plant Equipment and Machinery Required | (I) FRP/rubber-lined leaching reactors with heating & condensation facilities, (ii) high temperature oxidation furnace(~1000°C Max), (iii) Filter press with PP/FRP MOC with suitable slurry handling pumps, (iv) Pusher type reduction furnace (~1000°C Max), and (v) Drying oven (150°C, Max). | |

| 10. | Techno-Economics | For a 5MT/month capacity plant; Capital 85.0 Lakhs (excluding land & shed) & Recurring Expenditure Rs. 18.0 Lakhs/month (excluding scrap cost). | |

| 11. | Technology Package | Complete flow-sheet with mass balance, Equipment details, Process description, Equipment flow-diagram, Cost estimate & Product specification. Assistance in setting up the plant on separate terms. | |

Chemical requirement cost is about Rs.30.17 against product cost of about Rs.1.25.17 per ton of iron oxide production.