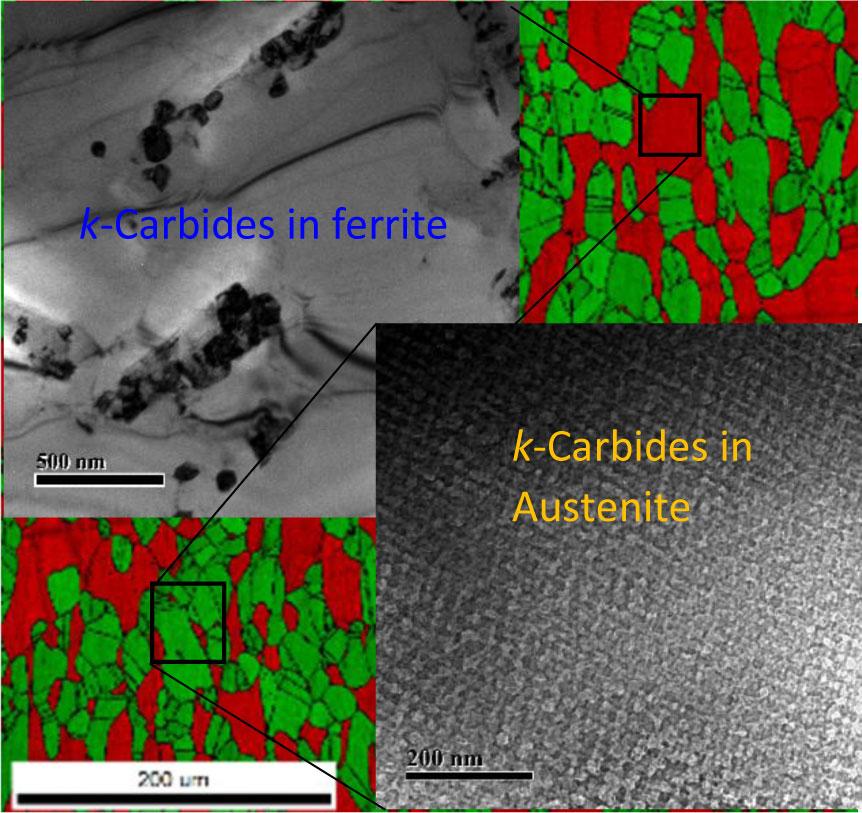

Research on Low-density high strength steels for their high performance is looked at by way of alloy and microstructure design. An effort is on to utilize a brittle intermetallic phase as a strengthening phase in high Al low-density steels. The objective is to develop duplex steel having microstructural constituents as ferrite, austenite and very fine precipitates of intermetallic (Kappa-carbide (FeMn)3AlC, B2-FeAl, D03-Fe3Al). Presence of intermetallic in steel deteriorates the mechanical properties, however, this can be overcome by controlled processing to obtain very fine, uniformly distributed intermetallic. A uniform dispersion of the intermetallic is expected to enhance the properties.

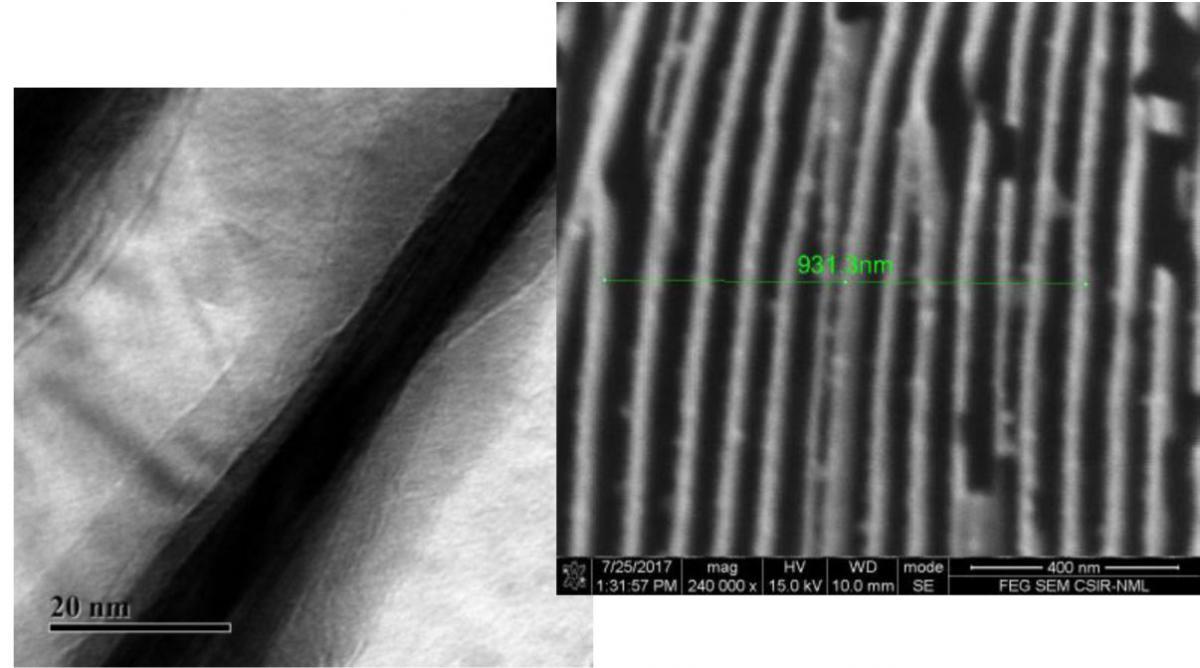

For applications involving the requirement of high wear resistance, concurrent enhancement in the hardness and toughness is mandatory. This is attempted by developing Bulk nano–pearlitic steel with interlamellar spacing in the range of 40 – 70nm in a continuous cooling process. The refined interlamellar spacing along-with fine pearlitic colony size imparts excellent hardness with adequate impact toughness to the steel.

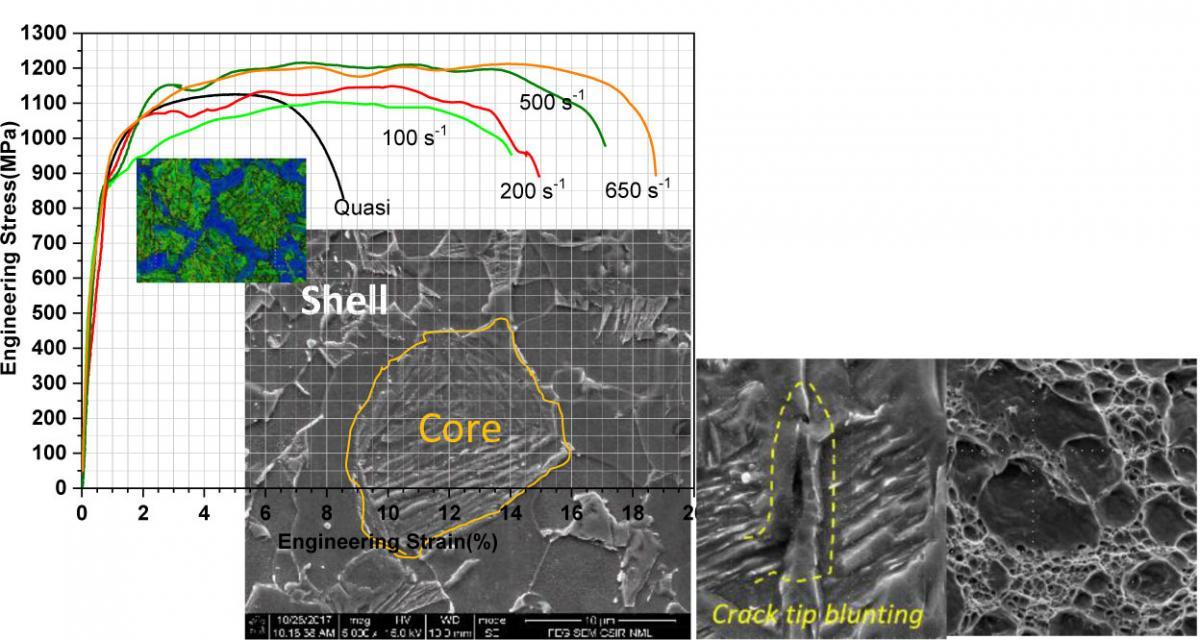

Research efforts on ultra-high strength dual phase steel via microstructure engineering are underway. A core-shell type microstructure was created through controlled austenite decomposition, wherein core consists of hard martensite phase and fine ferrite surrounding the martensite as a shell. Such micro-structures found to exhibit high ductility at high strain rate tensile deformations. The ferrite channels at inter martensite grains retard the crack growth rate and prevent the crack from entering into adjacent martensite phase. This delays the onset of global level damage and results in necking and fracture. This crack growth delay mechanism seems to promote strain hardenability in the steel at ultra-high strength levels and enhances ductility.

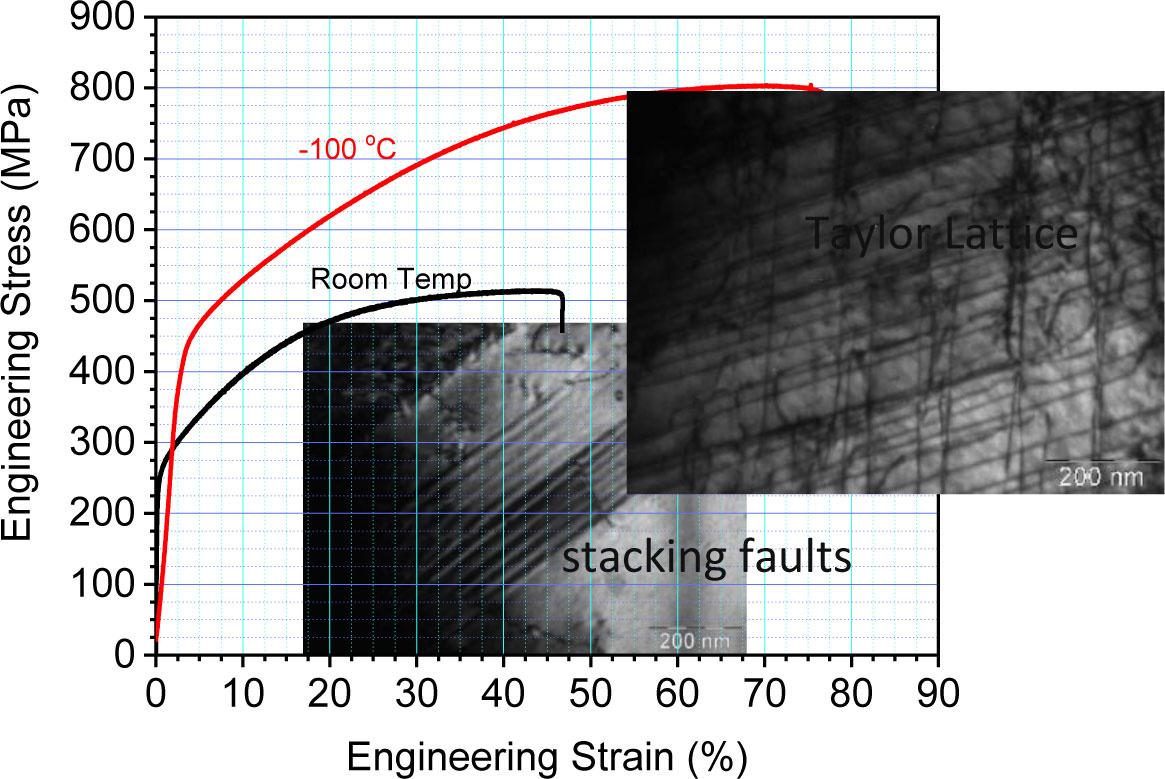

High entropy alloys are multi-principle component systems with a microstructure consisting of random solid solution phase/s. The study on HEA at CSIR-NML aims at the development of HEAs for cryogenic applications and study of deformation behavior of the alloys. Recent studies revealed that certain HEAs are tougher when cold i.e. the toughness improved significantly when tested at -100 oC as compared to that of the room temperature toughness.