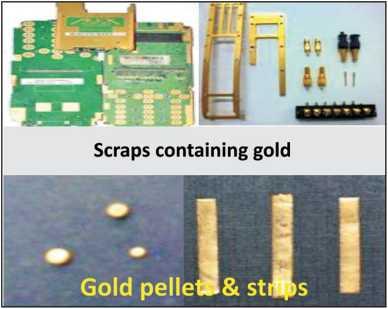

Recovery of Gold from Waste Mobile Phones and Scraps of Various Equipment

| 1. | Title of Product/Design/Equipment | Recovery of Gold from Waste Mobile Phones and Scraps of Various Equipment |  |

| 2. | IPR Status Patent/ Abroad IPR Details | Patent Filed | |

| 3. | Application/Uses | Recovery of Gold | |

| 4. | Salient Technical Features including Competing Features | A process is developed for the dissolution of metal from the PCBs of waste mobile phone, small parts of various equipments containing gold on outer layer. Chemical leaching followed by adsorption/ cementation with subsequent heat treatment was used to recover 99% gold. | |

| 5. | Level/Scale of Development | 1 Kg to 10 Kg (Lab Scale) | |

| 6. | Environmental Considerations | 20 to 25 L effluent generated is recycled after proper treatment. The solid residue will be utilized as non hazardous filling material in various applications. | |

| 7. | Status of Commercialization | Transferred to M/S ADV Metal Combine Pvt. Ltd., New Delhi | |

| 8. | Major Raw Materials to be Utilized | Mobile phone PCBs, scrap parts of various equipments, leachant, adsorbent, etc. | |

| 9. | Major Plant Equipment and Machinery Required | Leaching reactor, hood, filter press, pH meter, balance, glassware, safety appliances, etc. | |

| 10. | Techno-Economics | Capital Cost ~Rs. 10 Lakhs Recurring Cost ~Rs. 2 Lakhs/Year | |

| 11. | Technology Package | (a) Process-Know-how, (b) Details of equipment & (c) Quality Assurance Methods. Assistance in setting up the plant on separate terms. | |

Chemical requirement cost is about Rs.30.20 against product cost of about Rs.1.25.20 per ton of iron oxide production.