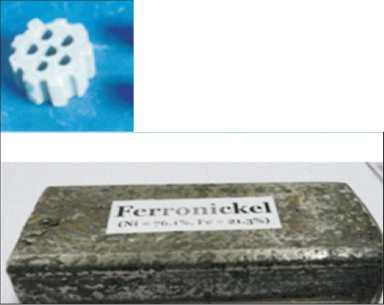

Ferronickel from Spent Nickel Catalyst

| 1. | Title of Product/Design/Equipment. | Ferronickel from Spent Nickel Catalyst |  |

| 2. | IPR Status Patent/Abroad IPR Details | Patent Filed | |

| 3. | Application/Uses | Ni recovery | |

| 4. | Salient Technical Feature including Competing Feature | A simple smelting process is developed for recovery of nickel as ferronickel of various grades from different nickel catalysts containing nickel in the range, 8 -18%. By controlling the parameters and the process techniques, ferronickel of 20 - 75% Ni grade have been produced with > 90% Ni recovery. The process consists of mixing the spent catalyst with additives, heating and reducing the mixture to get ferro-nickel | |

| 5. | Level/Scale of Development | 10 kg spent catalyst per batch smelting | |

| 6. | Environmental Consideration | Per ton of spent catalyst smelting would produce about 250 kg of C02 gas. The slag generated is non-toxic and can be dumped | |

| 7. | Status of Commercialization | Ready for commercialization | |

| 8. | Major Raw Material to be Utilized | Spent nickel catalyst, mill scale (iron oxide), coke etc. | |

| 9. | Major Raw Plant Equipment and Machinery Required | Grinding and palletizing, Smelting furnace | |

| 10. | Techno-Economics | For a 10 MT/month capacity plant; Capital cost is ~90 L (excluding land & shed) Recurring Expenditure -Rs. 4.0 Lakhs/month (excluding the cost of spent catalyst). | |

| 11. | Technology Package | Process-Know-how, (b) Details of equipment, (c) Plant Layout and (d) Quality Assurance Methods | |