Metallurgical and fractographic examination of 304LN and its weld under cyclic and monotonic loading in air/water and air environment

Understanding of the fatigue crack growth phenomena in advanced heavy water reactor (AHWR) in air/water environment requires fractographic and metallurgical investigation in piping steels and welds on the virgin and FCG tested specimens.

Objectives: (i)Metallurgical and fractographic investigation on specimen after fatigue and fracture toughness tests for qualification of piping material of advanced heavy water reactor (AHWR) and (ii) assessment of fatigue crack growth and life of cracked pipe during damage under water environment containing dissolve oxygen (DO), strain rate, loading frequency) and temperature.

Deliverables: (a) Quantitative microstructural data base; grain size, inclusion rating, phases w.r.t. base, HAZ, weld1(NG) and weld2 (CG) materials; (b) Quantification of DIM (c) determination of striation spacing, micro-cracks/secondary cracks, details of crack paths, width of stretched zone on the fracture surface of base, HAZ and weld materials; (d) Characteristics of oxide and oxide scale thickness near crack tip location; (e) Micro-hardness distribution along the growing cracks, etc;

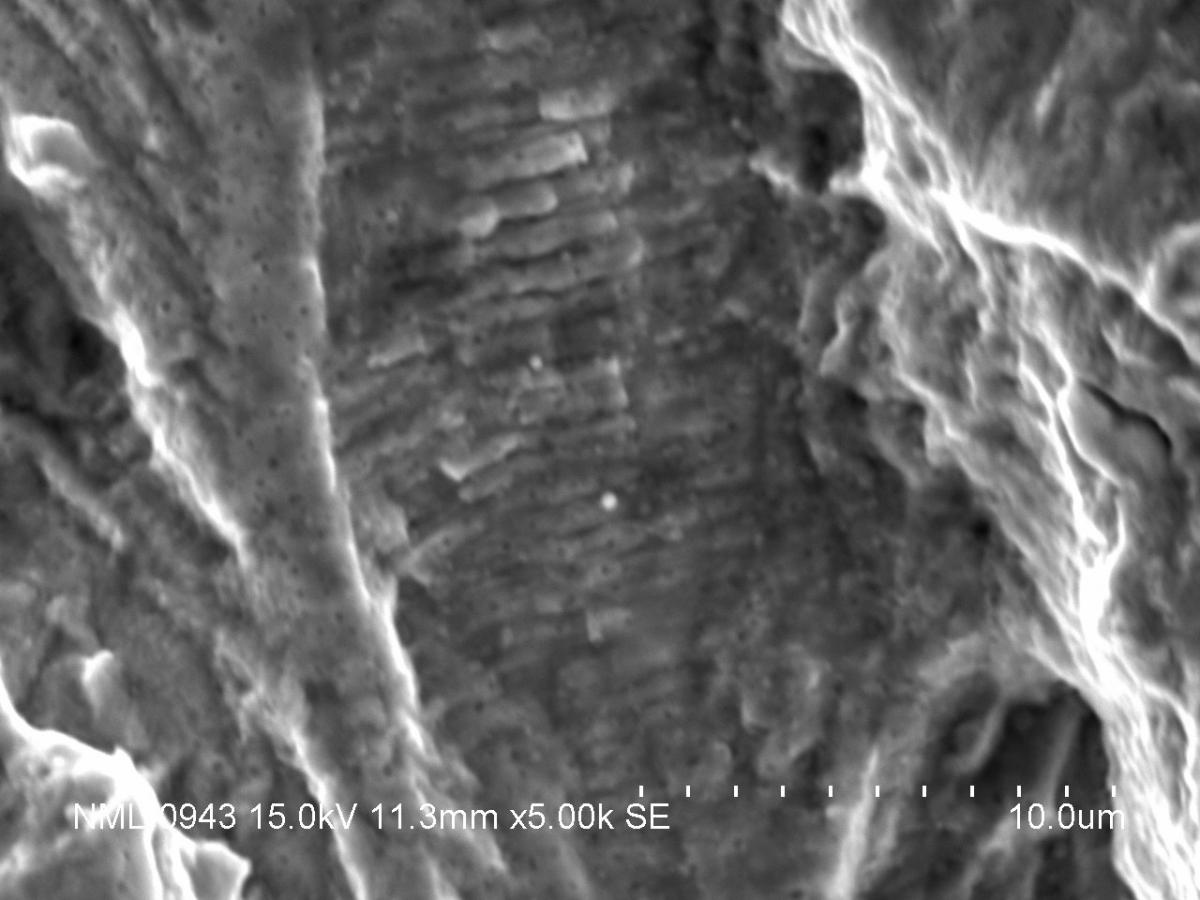

SEM micrograph showing striation in FCG sample tested in air at room temperature; Black arrow mark is showing the global direction of crack growth.

SEM micrograph showing striation in FCG sample tested in air at room temperature; Black arrow mark is showing the global direction of crack growth.