Beneficiation of Dumped Low-Grade iron ore Fines for iron and steel Making

|

1. |

Title of Product/Design/Equipment |

Beneficiation of Dumped Low-Grade iron ore Fines for iron and steel Making |

|

|

2. |

IPR Status Patent/Abroad IPR Details |

- |

|

|

3. |

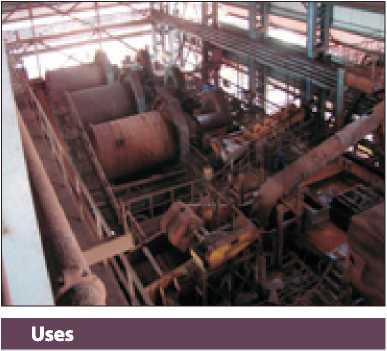

Application/Uses |

||

|

4. |

Salient Technical Features including Competing Features |

The process is based on upgradation of dumped low-grade iron ore fines involving scrubbing-washing-classification of the dumped fine ore followed by gravity and magnetic separation of classified materials. The process ensures optimum recovery of iron values through closed loop operation and processing of intermediate products. |

|

|

5. |

Level/Scale of Development |

0.5 tph. Further scale-up is possible. |

|

|

6. |

Environmental Considerations |

The process is environmental friendly. However tailing disposal system needs to be in place |

|

|

7. |

Status of Commercialization |

The technology has been commercialized and a plant with capacity of 1.35 mtpy has been commissioned. |

|

|

8. |

Major Raw Materials to be Utilized |

Low-grade iron ore |

|

|

9. |

Major Plant Equipment and Machinery Required |

Crushers, Grinding mills, Scrubber, Jig, Spiral, Hydrocyclone, Wet High Intensity Magnetic Separator, Dewatering units. |

|

|

10. |

Techno-Economics |

The capital investment for a plant of 1.35 mtpy capacity would be around Rs. 300 crores. Chemical requirement cost is about Rs. against product cost of about Rs. per ton of iron oxide production. |

|

|

11. |

Technology Package |

a) Process knowhow with details of equipment, (b) Technological process flow-sheet with material balance & (c) Quality assurance methods. Assistance in setting up the plant on separate terms |

|

Chemical requirement cost is about Rs. 30.6 against product cost of about Rs. 1.25.6 per ton of iron oxide production.